What is a Counting Scale?

A counting scale is a specialised weighing instrument that is often used to aid efficient inventory counts. Digital counting scales are widely used across many industries and have become an invaluable tool for many businesses to increase efficiency, accuracy, and productivity, especially around that stocktake time of year.

How Does a Counting Scale Work?

Counting scales aren’t too dissimilar to other weighing scales; their key distinction is that they also perform functions that involve division and multiplication operations using the weight of a single item to verify high volumes of identical parts.

First, the scale needs to be calibrated. This can be done with calibration weights or predefined calibration procedures.

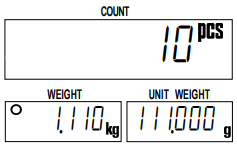

Next, measure out a sample unit to calculate the weight of an individual item. This average weight is then used to determine the quantity of pieces, based on the total weight placed on the scale. The scale allows the user to input the known average weight of the sample or automatically calculates it by weighing a predefined quantity of pieces. Once the average weight is established, the scale can accurately tally a larger batch of items by dividing the total weight by the average weight.

To ensure correctness, some counting scales are built with features such as tare functionality, which allows the user to subtract the weight of a container or packaging material, resulting in consistently accurate counts on all items.

Internal Resolution & External Resolution

Internal resolution refers to the scale’s ability to detect and measure minute weight differences. This is determined by the scale’s internal mechanism and is usually higher than the scale’s external resolution.

External resolution refers to the smallest weight increment that can be displayed on the scale’s external indicator or readout. For example, a scale with a resolution of 0.1g can accurately count items in increments of 0.1g.

Who Uses Counting Scales?

Counting scales are common sight in various industries, including manufacturing, warehousing, inventory management, and have become a useful tool for anyone working within the following fields:

Production

Counting scales are utilised in production environments to count and track components, parts, or materials used in the manufacturing process. They help maintain accurate inventory levels, monitor production output, and facilitate efficient workflow management.

Receiving and Shipping

Counting scales are used to accurately count and verify the quantity of incoming and outgoing items during the receiving and shipping processes. This ensures inventory accuracy and helps prevent errors in order fulfilment.

Warehouse Stock

Counting scales are used in warehouses to conduct inventory counts, especially for smaller items that are difficult to count manually. They enable quicker and more accurate stocktaking, and they reduce the time and effort required for inventory management.

Quality Control

Counting scales play a vital role in quality control processes by ensuring the accurate counting of components or products for inspection and testing. This helps maintain product quality standards and identifies any discrepancies or errors in the production process.

How Do You Correctly Use a Counting Scale?

Specific instructions may vary depending on the model and manufacturer of your counting scales, and it is always recommended that you consult the manual or instructions for the specific device you are using. That said, many counting scales are of similar design, and the following steps may typically be followed in order to use the counting scales to maximum effect…

Step 1: Set the Scale to Zero:

Always begin by ensuring that the scale is properly calibrated and set to zero. This is the best way to guarantee that any weight on the scale will be accurately measured.

Step 2: Place Container and Set to Tare:

Place the empty container/packaging material onto the scale and then press then activate the machine’s tare functionality. This function will subtract the weight of the container so that only the desired items being counted are measured, rather than the packaging.

Step 3: Weigh a Sample Size:

Take a sample of the items to be counted. This sample size will serve as a predetermined number of units or a percentage of the scale’s total capacity. Place the sample on the scale and record its weight.

Step 4: Place Total Items & Calculate:

Remove the sample from the scale and place the full batch of items to be counted onto the scale. The scale will then measure the total weight of the items.

How To Calculate the Items?

Counting scales’ internal mechanics will measure the total weight of the items by dividing the total weight with the average weight of a single item calculated in the previous step. This calculation provides an estimate of the quantity of items in the batch.

The Best Tips on Choosing the Right Counting Scales

When shopping around for counting scales, be sure to take into consideration the following factors…

Scale Capacity:

It is recommended to choose a scale that is appropriately sized to meet your weighing needs without excessive capacity. If you are counting items with varying weights, take into account the weight of the lightest and heaviest items and choose a scale with a capacity that suits that range.

Readability:

Readability refers to the smallest increment of weight that a scale can accurately measure. The smaller the increment, the higher the readability and accuracy of the scale. Readability can range from 0.1 gram to 0.0000001 gram, depending on the scale. It’s therefore advisable to select a counting scale with high readability, so as to ensure consistently accurate and precise measurements.

User-Friendly Interface:

Like with most devices, it’s always strongly recommended that you look for one with a user-friendly interface. Ideally your scale will have clear and intuitive controls and easy-to-navigate menus. This simplifies operation, reduces the learning curve for users, and thus minimises the amount of training time needed to use it.

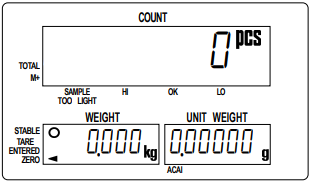

Readable Display:

A readable display can make the difference between a productive shift and an absolute slog of a day. Choose a counting scale with a clear and easy-to-read digital display that provides accurate and legible information, even in varying light conditions.

Remote Scale Option:

Some counting scales offer the flexibility of a remote display, allowing you to view the results from a distance or in a more convenient location.

A&D’s Counting Scales

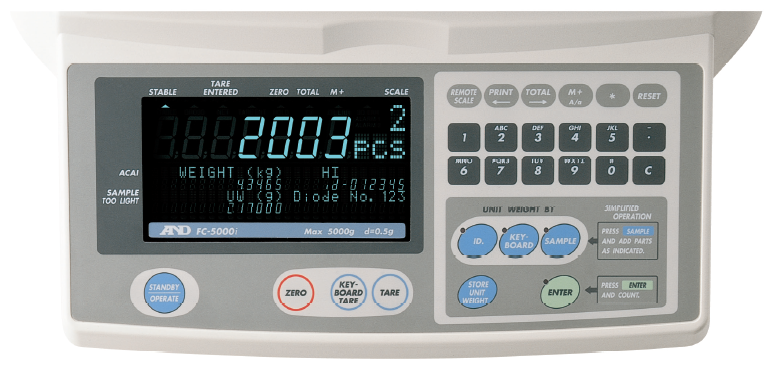

FC-i/FC-Si Series Time Saving Counting Scales with High Resolution

The FC-i/FC-Si Series Time Saving Counting Scales with High Resolution is a premium high performance model that can measure a minimum piece weight down to 0.0005g. It has a large memory for up to 500 IDs, and a buzzer which sounds when the current counting reaches, exceeds or lacks a set quantity. The buzzer can also alarm when an operational error occurs. This top of the line counting scale has a count accuracy of 1 in 10,000,000 and its counting scale capacities range from 500g to 50kg. Other notable features include easy data retrieval, simple operation mode, aluminium die cast frame, and many, many more.

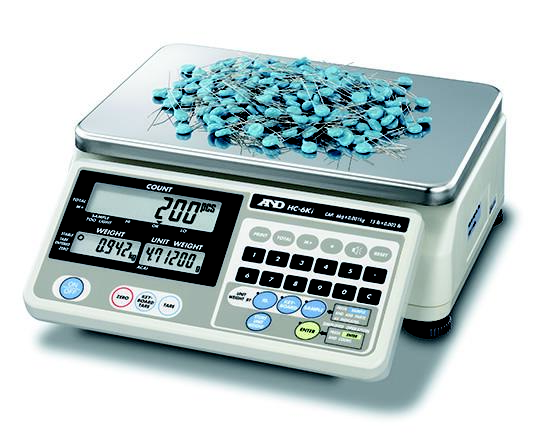

HC-i Series Counting Scale

The HC-i Series Counting Scales are as versatile as they are durable, featuring a wide range of functions that will enhance counting efficiency. Packing high-res weighing technology, the HC-i counting scales also feature a user-friendly interface and offer multiple weighing units and have the capability to store and recall data for efficient inventory management. The HC-i model also comes with connectivity options, enabling integration with external devices such as printers and PCs.

A&D Weighing has a large and extensive range of scales that are used in various industries that require accurate counting and inventory control. You can check out the full A&D Weighing range here. If you have any questions, don’t hesitate to get in touch with our friendly staff here.