LCM-13 Load cells are stainless steel shearbeams suitable for use on platform scales, hopper scales, bagging scales and all other weighing applications.

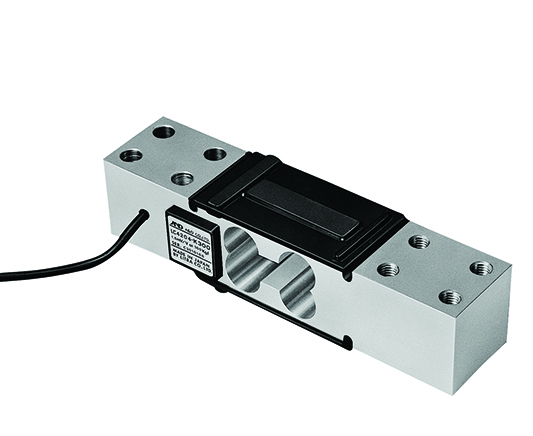

High capacity Aluminium Single Point Load Cells suitable for larger capacity platforms and weighing systems. Capacities of 300kg or 600kg available.

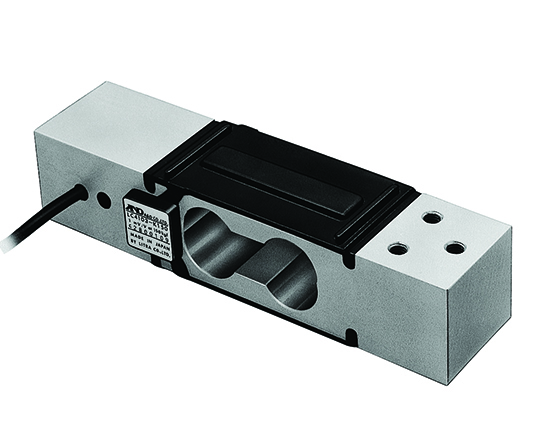

A range of Aluminium Load Cells featuring a compact design making them ideal for niche applications where space availability is a problem. Capacities range from 3kg to 35kg.

Stainless Steel hermetically sealed Single Point Load Cells suitable for use in hostile environments. Can be used in both tension and compression configurations.

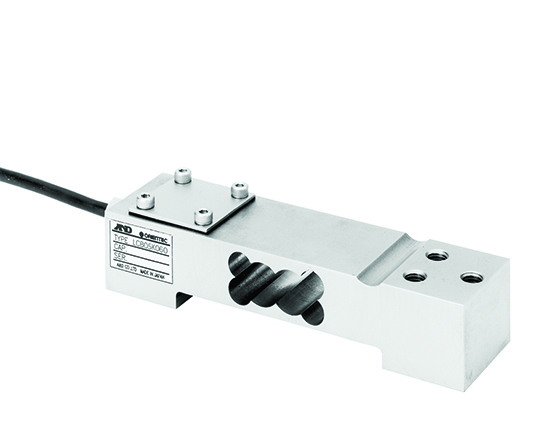

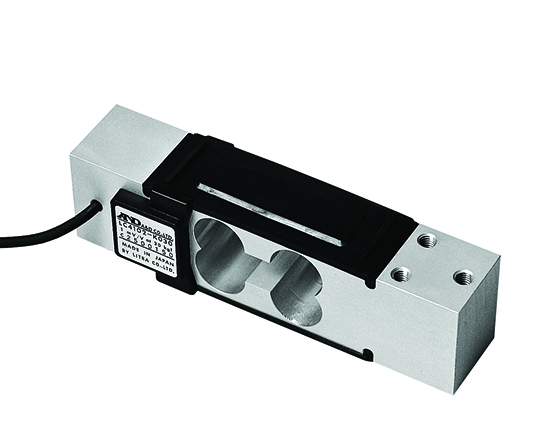

Aluminium Single Point Load Cells suitable for larger platforms and more robust weighing systems. Capacities ranging from 30kg to 150kg.

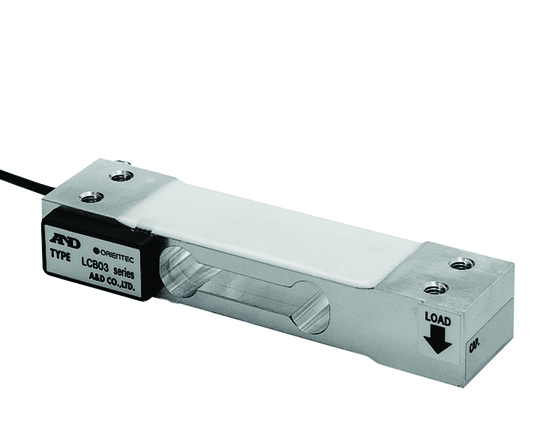

Aluminium Single Point Load Cells suitable as replacements in A&D light capacity platform scales and as components in light to medium capacity weighing systems. Available in capacities ranging from 10kg to 150kg.

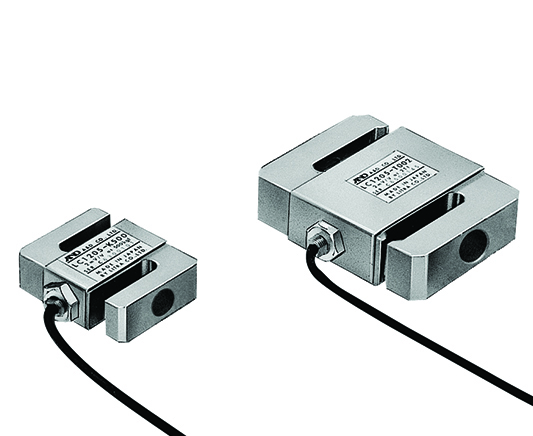

‘S’ Type load cells suitable for both tension and compression applications. Capacities range from 20kg to 5000kg. Construction materials are aluminium (low capacity) and tool steel. Easy installation and calibration.

3 Models available with 10, 20 and 30 tonne capacities. Trade approved. Stainless steel compression canister type. supplied with upper and lower mountings. Easy installation. Low Profile.