Michell Wool is Australia’s oldest and largest exporters of Australian Wool fibre, and has been associated with the international wool textile industry for over 140 years.

From the global headquarters in Adelaide, South Australia, the Michell family oversees a company with manufacturing and processing facilities in Australia and China, together with a network of local agents and business partners. The overall capacity of their facilities positions Michell Wool as a global leader in early stage wool processing.

Michell Wool is renowned as a consistent, reliable supplier of quality wool fibre, and recently called upon A&D to help update their processing machinery.

Michell Wool engaged A&D Weighing to help update their existing bulk bagging system, to add a weighing function, to ensure accurate and efficient measurement of weights during their production process. Michell Wool wanted to update their longstanding procedure so that they would be able to weigh the bags accurately when completely empty.

The bags are filled with magnesium which helps feed the system, and neutralises the acid that cleans the wool of all contaminants such as grass seeds, dirt, etc.

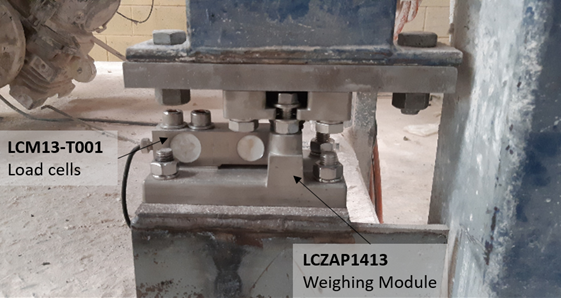

A&D installed a new, compact AD4430A DIN Rail Mounted Digital Indicator inside a discreet cabinet. Using the unit’s standard 4-20mA output, the signal goes to an aligned PLC and can determine if the bag has emptied completely or needs to be shaken with the vibrator, before filling can commence again. The bag mounting frame is positioned onto 4 x LCM13-T001 (1 tonne) loadcells to ensure the largest load expected is comfortably managed.

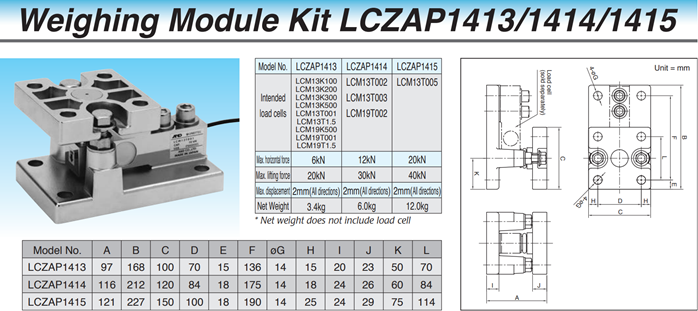

To ensure that the entire frame system is safely controlled and allowed only minimal “play”, the 4 x load cells are mounted on A&D LCZAP1413 Weighing Modules. These modules allow for the free movement of the frame on the load cells to be adjusted to optimum safety levels.

The 4 x LCM13-T001 load cells were then terminated into a compact 4 input junction box and routed to the AD4430A digital indicator via a single multi-core cable.

The AD4430A Analogue DIN-rail Compact Weighing Module features a High Performance Digital Filter (HPDF), which provides high accuracy/high speed weighing in environments where vibration can be an issue. As it copes with vibrations without requiring many mechanical measures, this reduces the costs and maintenance required for anti-vibration equipment. Other features include: flow rate output, control I/O (6 inputs, 8 outputs) as standard, and averaging hold, peak hold and comparator functions.

A&D Weighing offers an extensive range of weighing scales and measurement equipment to suit various applications and industries. To find out more about our products or any custom-built weighing solutions, please contact our team on 1800 241 434 or fill in our online form.